Closed Loop Chilled Water System Pressure

It is in a 35 stories building.

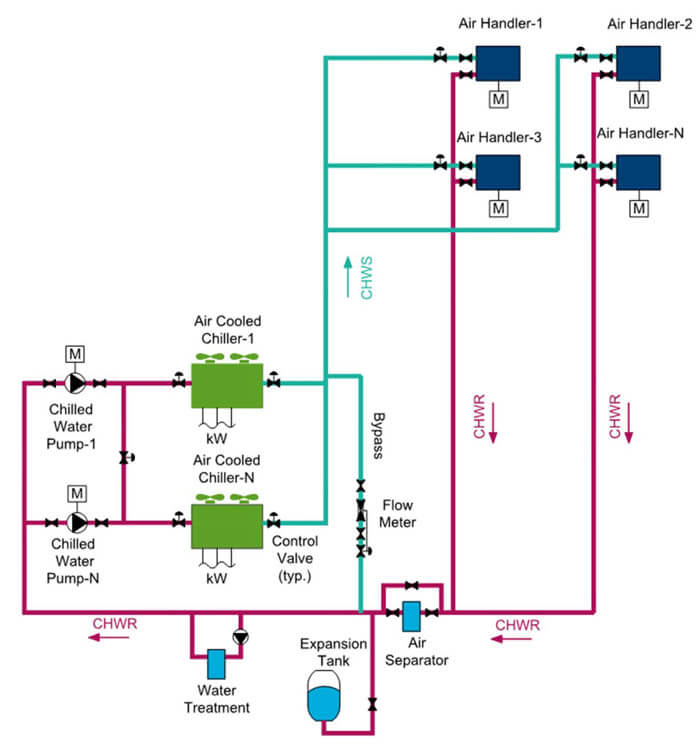

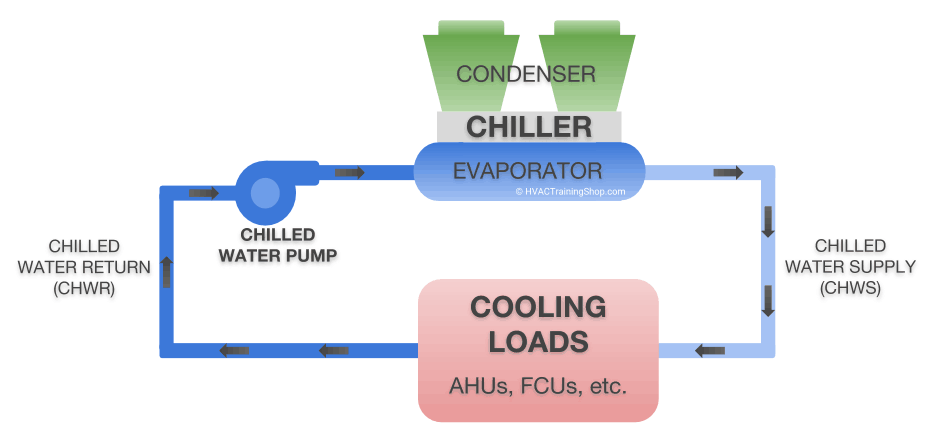

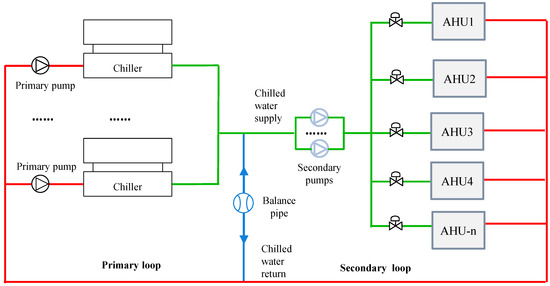

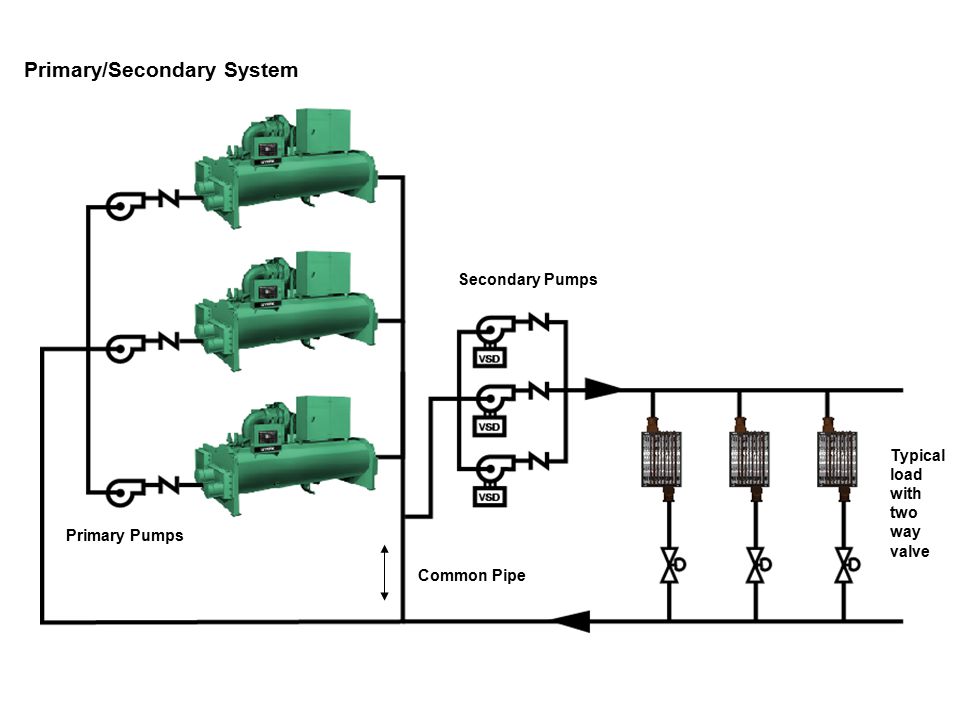

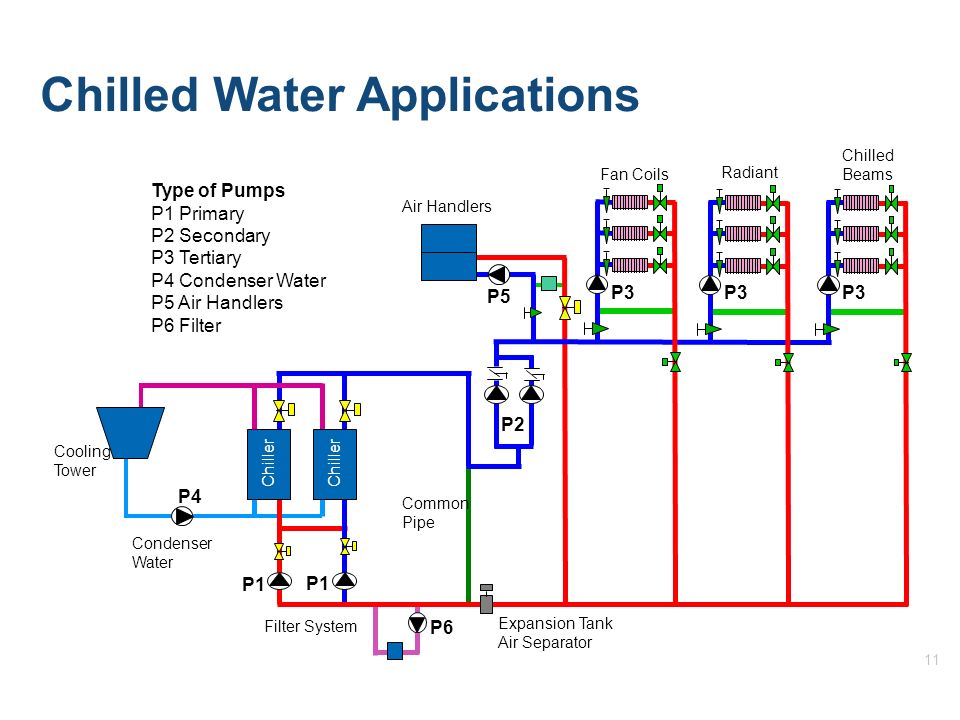

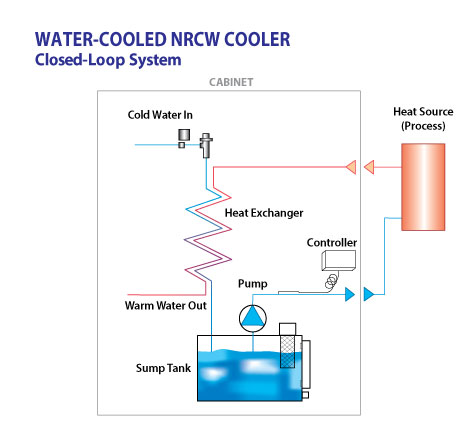

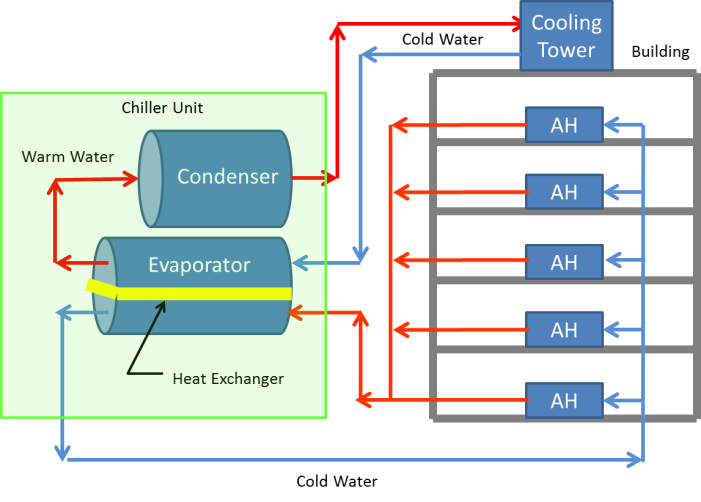

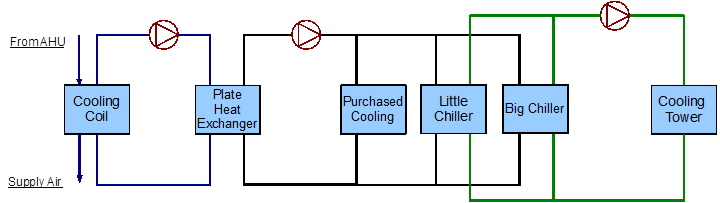

Closed loop chilled water system pressure. Since it seems that the chilled water circuit is a closed circuit and is going to be pressurised the pump will be considered as a circulating pump capable of creating enough head pressure to overcome the chiller s heatexchange friction loss stated by the maker and 0 5bar at least plus all the pipework and valves friction losses at the specified flow volume required for the chiller. However when leaks occur it can be costly and difficult to maintain the treatment levels necessary for corrosion and deposit control. If piped correctly closed loop chiller systems provide adequate chiller water flow at the optimum curve of the circulating pump without problems. Closed heating and cooling water systems typically require little makeup water and minimal chemical additions following the initial system charge.

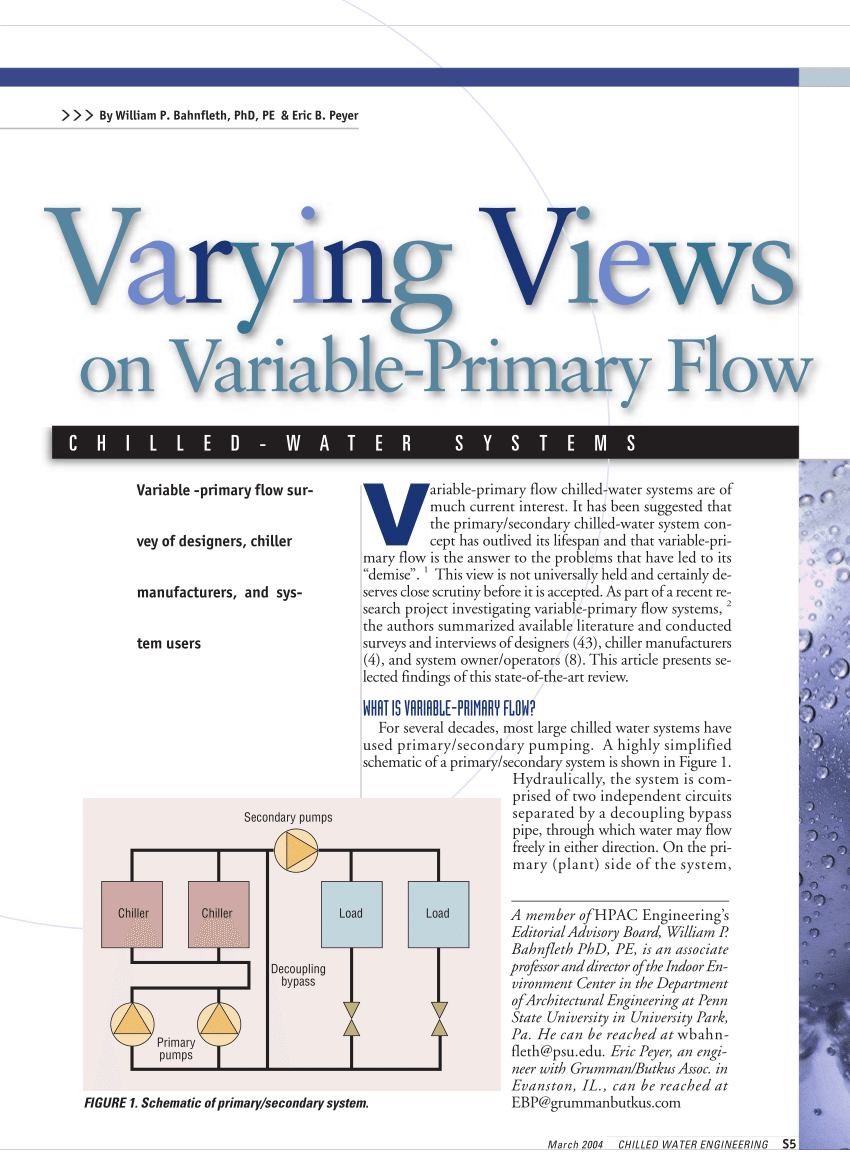

This would seem to be a simple concept but it is surprising how often a lack of attention to the basics can cause all kinds of problems. The problem usually traces back to improper system piping. Most modern hydronic heating and or cooling systems are closed systems that must be maintained at some minimum pressure. Other closed loop cooling systems can include chilled water systems for air chillers used at the air inlet to the gas turbines at a combined cycle power plant and the chemistry sample panel.

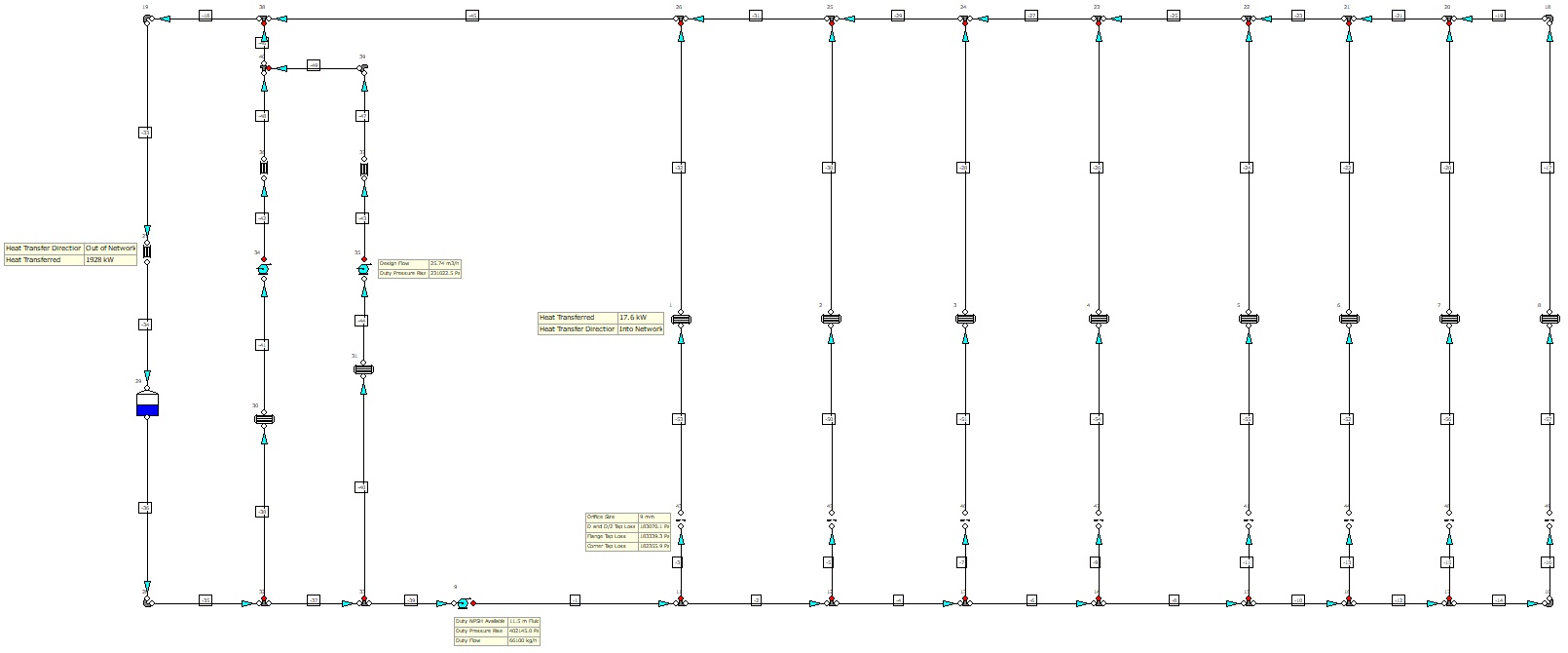

Lack of chilled water flow in closed loop chiller systems remains a common complaint among users. Examples of closed loop systems include hot oil circuits cooling chilled water systems hot water heating and air conditioning systems. Closed systems must be pressurized to satisfy three requirements. Figure 1 provides an illustration of a closed loop fresh water cooling system consisting of heat exchangers circulating pumps orifice plates and over 300 m of pipework.

A friend just called me about a closed loop chilled water system he is having trouble with.