Cnc Water Jet Cutting Machine Specification

We work under the iso 9001 2008 and as9100c quality control system.

Cnc water jet cutting machine specification. The following plasma machine can be combined with any waterjet machine we supply or stand alone with plasma cutting table of any size you specify such as 4 x4 1300x1300mm 4 x8 1300x2500mm 5 x10 1600x3200mm 2000x4000mm 3000x4000mm 3000x6000mm. Performance features include kmt 55 000 psi to 90 000 psi intensifier pumps flash cut cnc with built in cad cam and ebbco filtration systems. Before a job is shipped it is inspected to ensure the requirements are met and is in compliance with customer s specifications. Metal cutting machine tool.

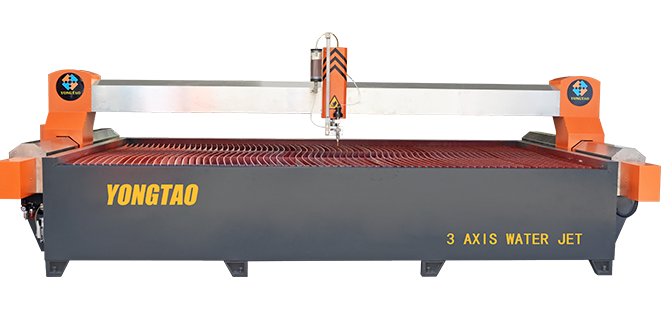

Cnc water jet cutting machine. The bidder shall meet the following bidder qualification criteria. The accurl go beyond cutting bevels on flat stock 5 axis water jet cutting opens up 3 dimensional cutting abilities at angles from 0 to 90 and will cut material such as aluminum armor plate brass carpet copper glass granite leather marble mild steel plastic stainless steel stone tile titanium. Sheet metal cnc cutting machine.

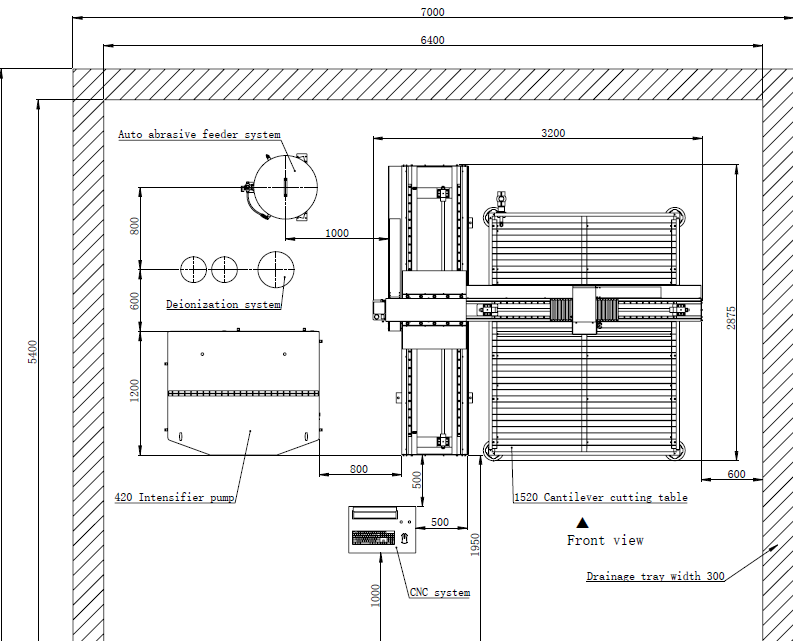

Cutting independently with an inexpensive machine the advantages. What is the structure of a water jet cutting machine. Technical specifications of water jet cutting machine sn description quantity 01 scope supply installation and commissioning of cnc water jet cutting machine with essential accessories and spares as per this specification. Cnc machining milling turning cnc waterjet cutting 3d printing prototyping fabrication secondary operations chautauqua machine specialties has been providing contract cnc machining since 1991 chautauqua machine specialties is a full service custom cnc machine shop and contract manufacturing supplier that specializes in ferrous and non ferrous metals and plastics.

Yes at waterjet natural cutting inc. Hydraulic combined shearing punching machine. Even though its not the fastest way to cut it has other advantages. Using the water jet high.

It is a cold cutting process where water under high pressure cuts various materials. In general the water jet is slower than laser or plasma cutting thought the speed can be increased on a waterjet cnc with 3 or 4 cutting heads. Waterjet cutting vs laser cutting. Waterjet cutting system the k jet delivers cut speeds up to 500 ipm with standard cutting areas up to 72 x 144 and a table capacity up to 250 lbs.

High pressure water is fed into the water jet machine through an inlet. Water jet cutting with the water jet cutter flowjet from cnc step offers you a real alternative and even some real advantages in terms of cutting unique materials in direct comparison to other processing methods. All the products will meet the customer s purchase order applicable statutory and regulatory requirements. The process of cutting materials can be automated using a cnc water jet and 5 axis water jet cutting machines can produce more intricate 3 d shapes using motion control technology.